Laser cut without bars …? How does that work?

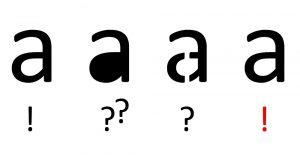

When a laser cuts paper, fine handles must be inserted into the subject. For example, so that an “a” remains a letter with a punze -and not just a hole in the form of an “a”.

That is usually not so pretty. But to intervene visually in a logo is not everyone’s skill.

IIf lasered motifs are then laminated onto a coloured background so that the background shimmers through in colour, very delicate motifs can be damaged. Only setting more or stronger bars is often not enough – and does not make the motif more beautiful. The same applies if the contours are coarsened.

Of course, it would be much easier to lash out at the finished duplex carton: No stops needed, no problems with conceding. So why not make it easy?

Logical, because laser cutting generally produces traces of powder, i.e. fine burn marks. Depending on the paper, these are more or less pronounced. The paper that is best suited according to our many years of experience is definiteley Colour Matters: it’s made for laser cutting.

But when a surface has to be removed, the exposed lower surface, whether yellow, orange or green before, approaches the colour “powder trace brown”.

With a new laser system, our partner has succeeded in lowering the laser temperature to such an extent that the color of the lower layer can still be recognized as this. Depending on the colour and motif, sometimes not yet optimal – but still increasingly close.

And another goody: In the meantime, it is also possible for us to print cardboard in thicknesses up to 1 mm with the finished laminate offset – this corresponds, for example, to Colour Matters 350 + 350 g/qm.

Suddenly complicated projects with multi-layer materials and laser finishing become as easy as in the old world of image printing:

Print – laser – cut – done!

Please give us your trust: As a  production agency, we have an excellent reputation, which we vigorously defend.

production agency, we have an excellent reputation, which we vigorously defend.

You’ve just got something in mind? Then get in touch with us.

More examples of business cards – also in other techniques than lasercut – can be found here.