Laser cut and laser engraving of paper and cardboard – finer and more precise

Punching and engraving with laser light opens up undreamt-of possibilities in the processing of paper and cardboard. Finest cuts and razor-sharp three-dimensional relief engravings are possible, which are not achievable with known punching methods.

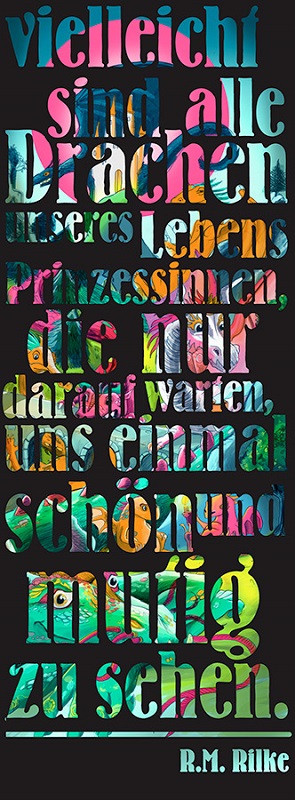

Logos, even the smallest and most curved lettering and even raster images can be reproduced easily and perfectly, and this with unsurpassable accuracy of reproduction of the motif in combination with other engraving methods, or embossing techniques.

Further advantages of Lasercut compared to

mechanical punching process:

• Especially when running small editions, highly attractive in terms of prices, as no tool is necessary.

• Ideal for high-quality natural papers, which have many advantages over painted papers.

Disadvantages of laser cut compared to conventional mechanical punching methods:

•More or less strong inclination to fo am marks depending on material and motif (these are fine fire margins in the paper)

am marks depending on material and motif (these are fine fire margins in the paper)

• With higher runs long production time, even the price advantage is lost.

However, there is a special mechanical technique of filigree punching, which combines the advantages of laser cut with the advantages of mechanical punching.

Read more here

Do you have any questions about laser and punching? Or do you have an object you want to realize? Use our consulting and production service.